Large Format Digital Printers for Corrugated Cardboard Packaging

Sustainable Printing Solution

Advantages of Hanway corrugated printing technology

High Speed Printing

High Quality Printing

Superior print accuracy with advanced Kyocera printhead technology and resolutions up to 600 dpi.

Water-based Inks

Water-based inks with exellent colour range and quick drying, safe for food and medical packaging.

Wide Colour Gamut

Excellent colour reproduction with up to 6 colours including CMYK and optional Light Cyan and Light Magenta or Orange and Green.

Modular Multi-pass Printers for Corrugated Cardboard

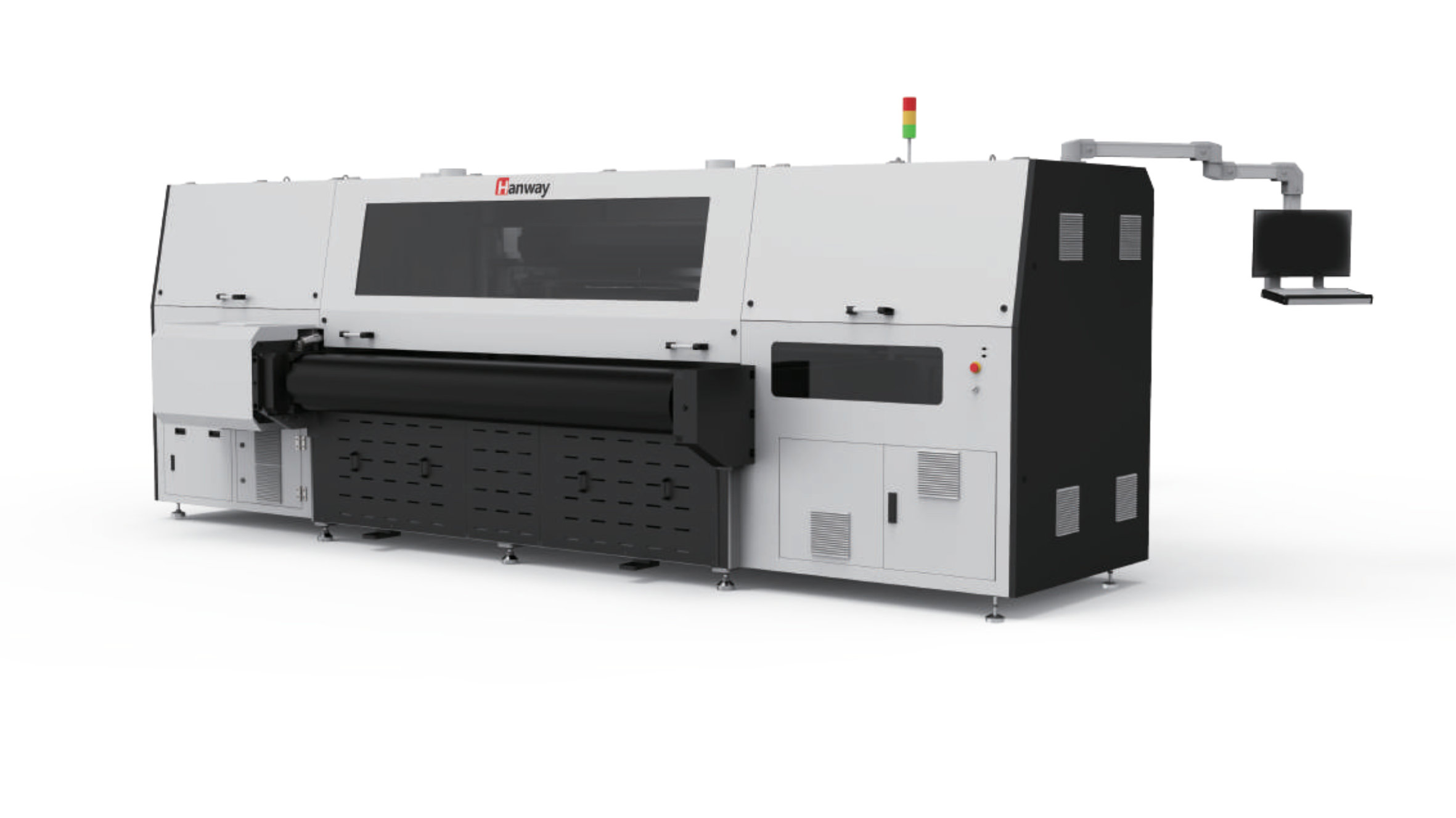

MULTI-PASS

HighJet 2500D

The production capacity up to 800 m2/h. High quality printing on coated and uncoated cardboard. All-in-one solution with drying and varnish in line with excellent functionality.

Printing Speed and Media

Media: Coated, White, Kraft, etc.

Max . Width: 2500 mm

Standard Feeding Length (Auto Mode): 2500 mm

Max. Feeding Length (Manual Mode): 4000 mm

Thickness: 1.5 – 15 mm

Drying: Infrared drying system

Specifications

Dimensions 5.4 m (L) x 5.52 m (W) x 2.05 m (H)

Packed dimensions 5.94 m (L) x 2.28 mm (W) x 2.21 m (H)

Additional Units 4.60 m (L) x 1.90 m (W) x 2.20 m (H)

Net Weight 7000 kg

Gross Weight 8000 kg

Operational site: 11.40 m (L) x 8.52 m (W) x 2.50 m (H)

Air pressure: 0,6 ~ 0,84 Mpa, 150 l/min, Flow rate >34 litres/min

Relative humidity: 60% – 80%

Ambient temperature: 20°-30°C

Operating Power AC 380V-400V 3P+PE, 54A, 50/60 Hz

Total Power 27kW

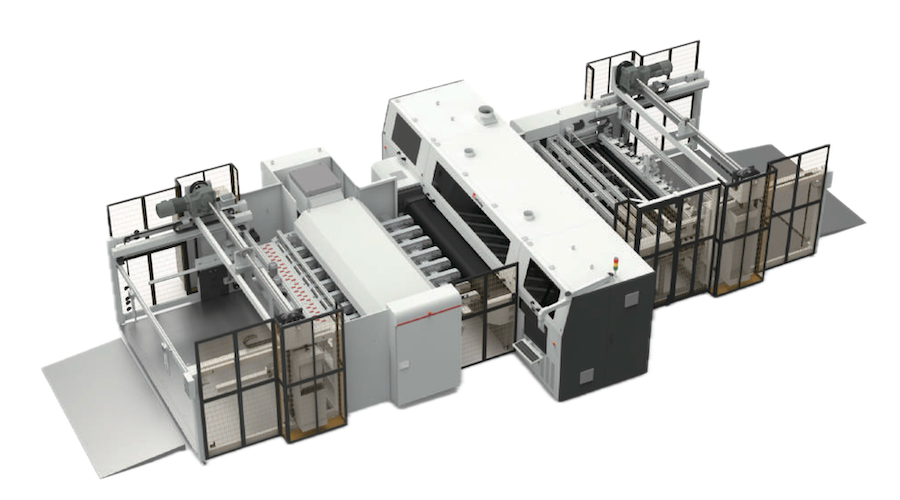

MULTI-PASS

Revo 2500W

The production capacity up to 1400 m2/h. High quality printing on coated and uncoated cardboard. All-in-one solution with slotting, drying and varnish and stacking, in line with excellent functionality.

Printing Speed and Media

Media: Coated, White, Kraft, etc.

Max . Width: 2500 mm

Standard Feeding Length (Auto Mode): 2500 mm

Max. Feeding Length (Manual Mode): 4000 mm

Thickness: 1.5 – 15 mm

Drying: Infrared drying system

Specifications

Dimensions 5.4 m (L) x 5.52 m (W) x 2.05 m (H)

Packed dimensions 5.94 m (L) x 2.28 mm (W) x 2.21 m (H)

Additional Units 4.60 m (L) x 1.90 m (W) x 2.20 m (H)

Net Weight 7000 kg

Gross Weight 8000 kg

Operational site: 11.40 m (L) x 8.52 m (W) x 2.50 m (H)

Air pressure: 0,6 ~ 0,84 Mpa, 150 l/min, Flow rate >34 litres/min

Relative humidity: 60% – 80%

Ambient temperature: 20°-30°C

Operating Power AC 380V-400V 3P+PE, 54A, 50/60 Hz

Total Power 27kW

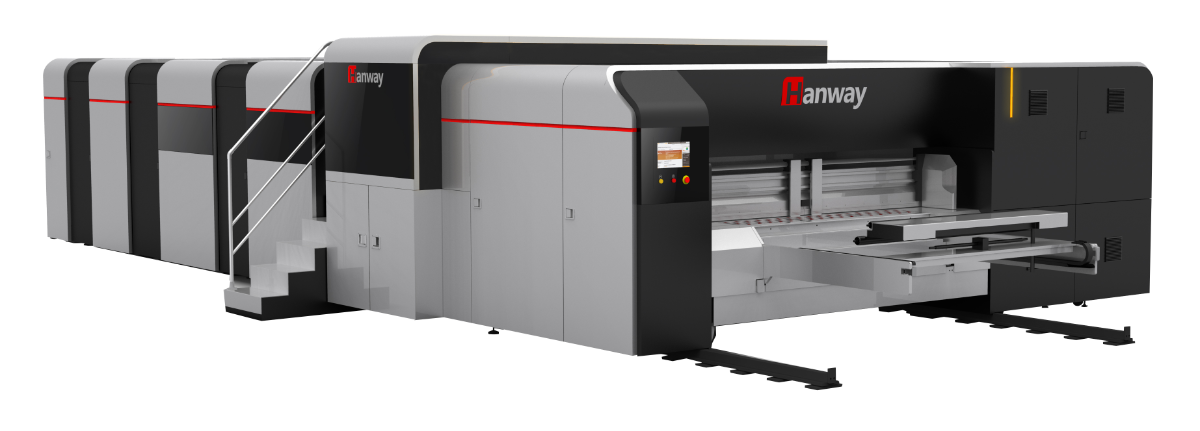

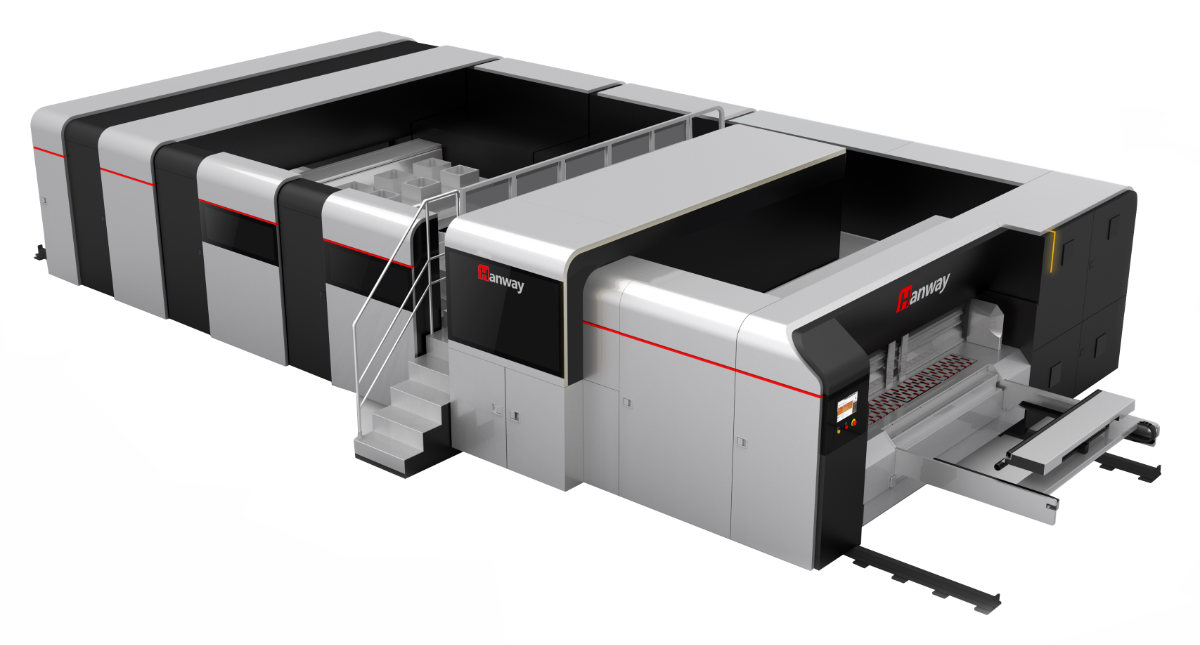

MULTI-PASS

Revo 2500W Pro

The production capacity up to 1050 m2/h. High quality printing on coated and uncoated cardboard. All-in-one solution with slotting, drying and varnish and stacking, in line with excellent functionality.

Printing Speed and Media

Media: Coated, White, Kraft, etc.

Max. board size: 2500 mm (W) * 2000 mm (L)

Min. board size: 400 mm (W) * 400 mm (L)

Board thickness: 0.3 – 15 mm

Feeding height: 750 mm (tray included)

Specifications

Machine Size 12670 (L) * 5700 (W) * 2200 (H) (Feeding direction as length)

Paper Feeder 4500 mm (L) * 2280 mm (W) * 2410 mm (H) / 2500 kg

Conveyor 4050 mm (L) * 1950 mm (W) * 2410 mm (H) / 1900 kg

Printer 5940 mm (L) * 2280 mm (W) * 2210 mm (H) / 5000 kg

Dryer 5000 mm (L) * 1900 mm (W) * 2060 mm (H) / 1400 kg

Paper delivery 4500 mm (L) * 2280 mm (W) * 2410 mm (H) / 2900 kg

Operational site: 16670 (L) x 8700 (W) x 2500 (H)

Air pressure: 0.6 – 0.84 Mpa, flow rate ≥ 900 L/min, clean air source without oil and water

Relative humidity: Relative humidity: 45 – 65%

Ambient temperature: 22 – 28 °C

Operating Power Three-phase AC380 – 400 V 3P+PE, 187 A, 50/60 Hz

Total Power 108 kW total power

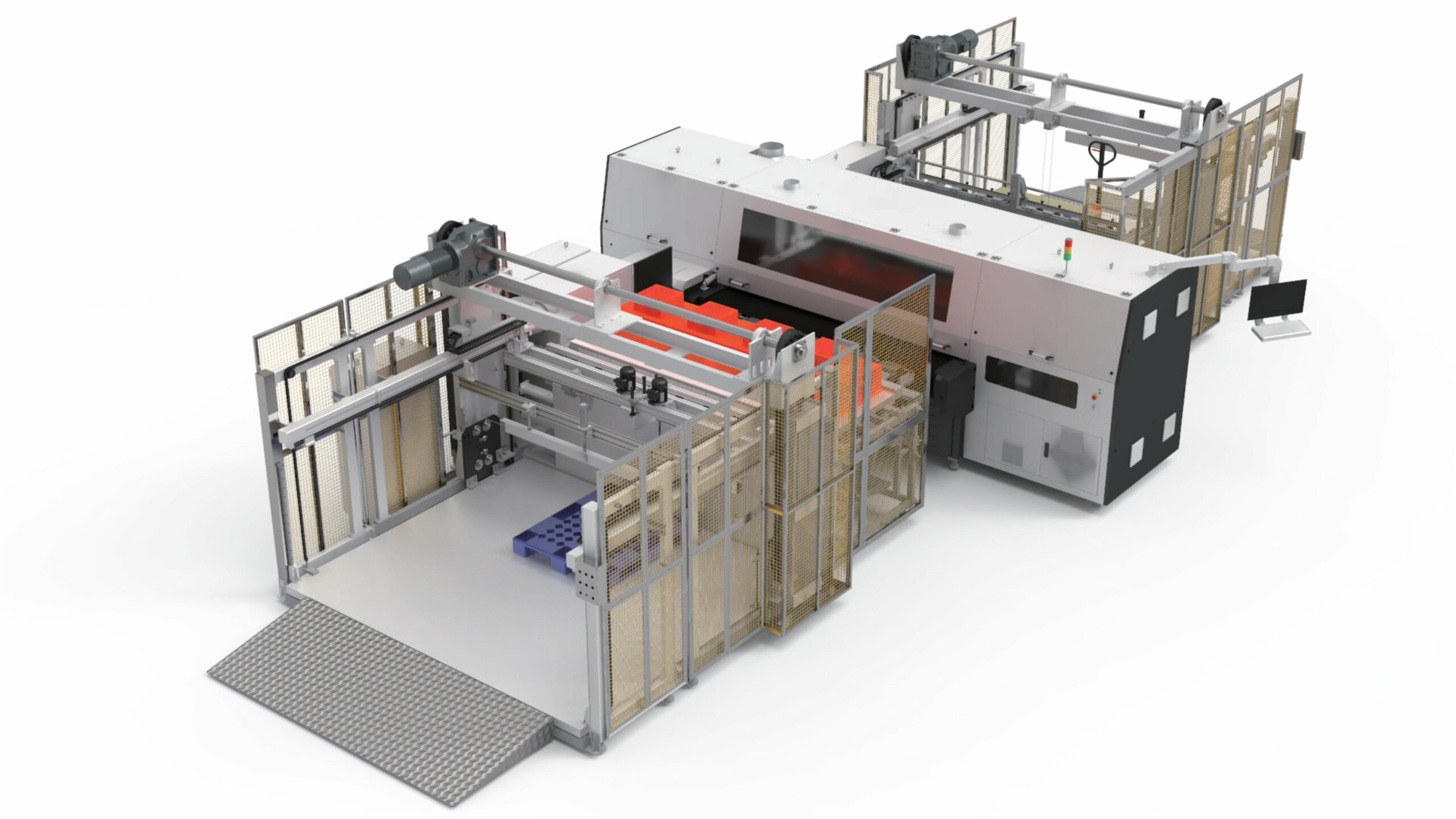

Addon Modules

Fully automatic rear feeder, in line with the printer Perfect synchronization between loading, printer and unloading Multiple configuration modes for labor saving, high efficiency and simplified production. Complete digital control of all operations.

- More precise and stable with servo control and professional control system

- Quick and precise with electric regulator adopted for the slotting size setup and driven by ball screws

- Integrated control interface allows quick setup of parameters

- Precise coating resolution and volume control for broad application

- Circular and stable coating during production

- Integrated control interface allows quick setup of parameters

Drying Unit

- Hot-air drying system with high efficiency and safety

- High production quality and suitable for various substrates especially for coated paper

- Environmental-friendly zone control system to transmit hot air according to the format of the product

- High speed, quality and safety with labor and time saving

- Orderly stacking, stable performance, simple structure and broad stacking space

- Integrated control interface allows quick setup of parameters

Single-pass solutions for corrugated cardboard printing

SINGLE-PASS

Elite 2504

The Star of Efficiency in Single Pass, Printing speed up to 100 m/s.

Printing Speed and Media

Media: Yellow cardboard, White cardboard

Max . board size: 2500 mm x 4000 mm

Min. media length: 400 mm

Thickness: 1.5 – 15 mm

Max. printing width: 1080 mm

Drying: Air dry

Specifications

Printhead Industrial-grade piezoelectric ceramic printhead

Ink Type Water-based pigment/dye ink

Print resolution 400 x 600 dpi / 600 x 600 dpi / 900 x 600 dpi

Suitable media width: 400 – 2500 mm

Feeding Mode Front edge

Air Pressure Requirement: 0.6 – 0.84 Mpa, Flow rate≥150 L/min, filted air

Environment Requirement: Relative humidity: 45 – 65%, Ambient temperature: 22 – 28 °C

Power Consumption: AC380 – 400 V 3P+PE, 150 A, 50/60 Hz, Total power: 34 kW

SINGLE-PASS

Glory 1606

Industrial and robust design with productivity of 150m/min with a single pass digital printing machine applicable to all types of corrugated cardboard including Craft, Craft White and Coated White.

Printing Speed and Media

Media: Coated, White, Kraft, etc.

Max . board size: 1600 mm x 2800 mm

Min. board size: 450 mm x 400 mm

Thickness: 1.5 – 11 mm

Max. printing width: 1512 mm

Drying: Infrared drying system

Specifications

Dimensions (L*W*H)

Glory 1606: 15.1 x 5.7 x 2.8 m

Glory 1606 + Dryer: 24.5 x 5.7 x 2.8 m

Glory 1606 + Dryer + Varnish: 26.5 x 5.7 x 2.8 m

Glory 1606 / 394 Kw / Actual 200 Kw

Priming unit 3 Kw / Actual 1.2 Kw

Tunnel Dryer 193 Kw / Actual 131 Kw

Varnishing unit 77 Kw / Actual 62 Kw

Stacker 5 Kw / Actual 3 Kw

Weight Glory 1606 / 22.8 T

SINGLE-PASS

Glory 2504

Industrial and robust design with productivity of 180m/min with a single pass digital printing machine applicable to all types of corrugated cardboard including Craft, Craft White and Coated White.

Printing Speed and Media

Media: Coated, White, Kraft, etc.

Max . board size: 2000 mm x 2500 mm

Min. board size: 400 mm x 600 mm

Thickness: 1.5 – 15 mm

Max. printing width: 2500 mm

Drying: Infrared drying system

Specifications

Dimensions (L*W*H)

Glory 2504: 8.1 x 6.4 x 2.6 m

Glory 2504 + Dryer + Varnish: 12.1 x 6.4 x 2.6 m

Glory 2504 + Dryer + Varnish + Slotter: 13.9 x 6.4 x 2.6 m

Weight Glory 2504 / 15.2 T

Weight Varnish 4 T

Weight Dryer 3.2 T

Weight Slotter 8 T

Glory 204 / 75 Kw / Actual 24 Kw

Dryer 110 Kw / Actual 14 Kw

Varnishing unit 77 Kw / Actual 62 Kw

Slotter 77 Kw / Actual 60 Kw

Corrugated Cardboard Applications

Sustainable Printing

Grow your packaging portfolio with proven technology and true water-based inks that open the door to new possibilities.

Electronics and home appliances

Deliver corrugated packaging that is strong enough for the warehouse and attractive enough for the store shelf.

POS display

Boost sales with easy-to-assemble POS displays and stunning packaging that excite customers.

Sensitive products

Produce attractive packaging that keeps delicate products safe and clean.

Automotive parts

Growing automotive industry demands custom packaging solutions in variety of designs, colours and sizes.

Promotional

Create limited series and promotional packaging that stands out and grabs attention.

Case Study

ZETACARTON S.P.A. Awarded at Oro della Stampa 2023

ZETACARTON S.P.A. was honored with the ‘L’Oro Printer on Corrugated’ award at the prestigious Oro della Stampa 2023 in Milan, recognizing their innovation in corrugated cardboard printing.

Advantages of digital printing

Digital printing is becoming increasingly popular in the corrugated post–print sector due to its ability to produce high–resolution graphics, smaller order sizes, short lead times, fast turnarounds, customization, and personalization. This technology is being used to increase product margins or as an alternative to current methods for lower total production costs.

Economy

The digital process offers an economical way to produce low–volume and custom print jobs with minimal setup costs and high–definition visuals. It also offers quick and easy setup, variable data, and versioning capabilities. Although digital printing requires its own specialized knowledge, it is an economical option for the corrugated pressroom.

Software Integration

- Advanced software interface

- Digital colour management

- Stable and precise

- Barcode and QR code printing

- Caldera RIP Compatible

Quick job switching

Jobs with same dimension

7 seconds

Jobs with different dimension

120 seconds

Custom Packaging with High-resolution Graphics, Smaller orders, Short Lead Times, Fast Turnarounds

Increase magins and lower production costs on the go.